Introduction

In today’s world, protecting products during shipping and storage is crucial for maintaining their quality and integrity. Foam protective packaging is a widely used solution in various industries, providing essential protection for items ranging from electronics to automotive parts. This article delves into the benefits, applications, and unique features of foam protective packaging, highlighting its importance in ensuring safe and damage-free delivery of products.

Understanding Foam Protective Packaging

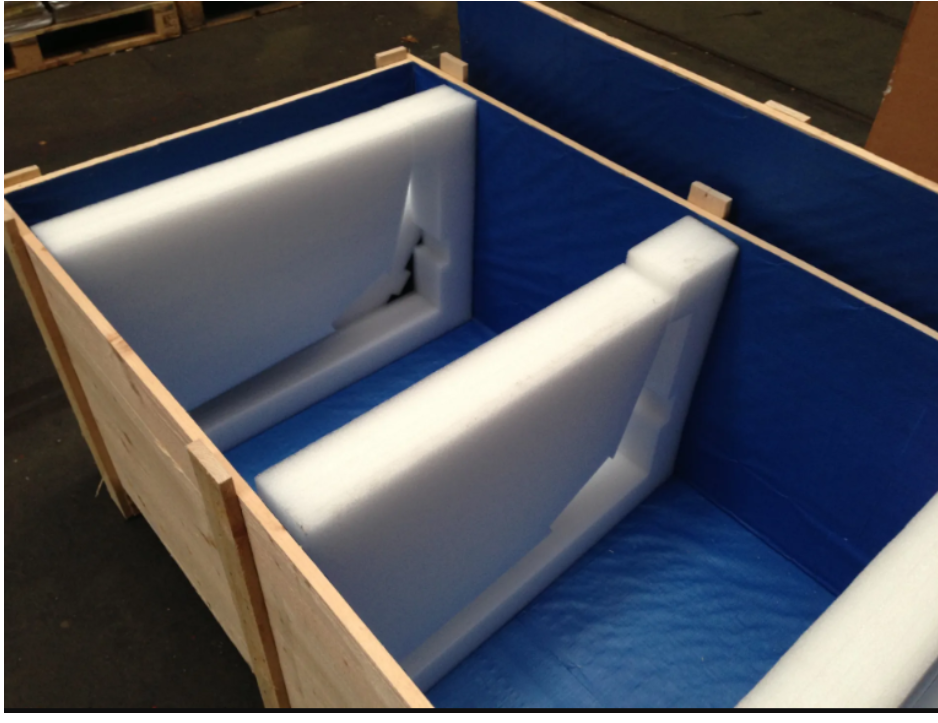

Foam protective packaging refers to the use of foam materials, such as polyethylene foam, to safeguard products from impact, vibration, and other potential damage during transportation and handling. Polyethylene foam is particularly popular due to its excellent cushioning properties, durability, and versatility. It is used extensively in industries like electronics, automotive, and healthcare, where protecting delicate items is paramount.

The Benefits of Foam Protective Packaging

Superior Impact Absorption

One of the primary advantages of foam protective packaging is its ability to absorb and distribute impact forces. The foam’s structure consists of numerous cells that act as tiny shock absorbers, effectively reducing the risk of damage during transportation. This makes it an ideal choice for fragile or delicate items that require careful handling.

Moisture and Chemical Resistance

Foam protective packaging, especially polyethylene foam, is resistant to moisture and chemicals. This resistance is crucial for products sensitive to these elements, such as electronic devices. The foam creates a barrier that prevents moisture ingress, thereby prolonging the lifespan and functionality of the packaged product.

Versatility and Customization

Polyethylene foam protective packaging is available in various colors, including black, white, blue, and anti-static pink. It can be tailored to fit the specific needs of different products, offering bespoke designs or standard packaging solutions. This versatility ensures that the packaging not only provides optimal protection but also enhances the product’s presentation.

Multi-Use and Durability

Polyethylene foam is a cross-linked foam known for its durability. It is suitable for reuse in multi-trip packaging and factory transit applications. Despite being more expensive than polystyrene, its ability to withstand multiple impacts without degrading makes it cost-effective for protecting high-value items.

Applications of Foam Protective Packaging

Electronics Industry

In the electronics industry, protecting sensitive devices from damage during shipping and handling is critical. Foam protective packaging provides the necessary cushioning and protection for items such as smartphones, tablets, and computer components. Its resistance to moisture and temperature fluctuations ensures the safe delivery of electronic devices.

Automotive Industry

The automotive industry relies on foam protective packaging to safeguard parts and components during transit. From delicate sensors to bulky engine parts, foam packaging provides the cushioning needed to prevent damage. The ability to customize the packaging ensures that each part receives the appropriate level of protection.

Healthcare Sector

In healthcare, foam protective packaging is used to transport medical equipment, instruments, and pharmaceuticals. The foam’s cushioning properties protect these sensitive items from impact, while its resistance to chemicals ensures that the packaging remains effective even in challenging environments.

The Complete Service: Advanced Protective Packaging

Advanced Protective Packaging, established in 1986, has been a leader in the design, manufacture, and supply of foam protective packaging. The company offers a comprehensive range of services, ensuring that customers receive tailored solutions for their packaging needs.

Customized Packaging Solutions

Advanced Protective Packaging analyzes product requirements to produce bespoke designs that optimize performance and cost. Whether it’s a standard packaging solution or a custom design, the company ensures that products arrive safely.

Comprehensive Product Range

The company supplies not only polyethylene foam protective packaging but also boxes, cartons, tape, and bubble wrap. This complete range of products simplifies the packaging design process and ensures that customers receive a cohesive solution for their needs.

Expert Knowledge and Experience

With nearly 40 years of experience, Advanced Protective Packaging has a team of experts who understand the nuances of foam materials and their applications. The company’s commitment to intelligent design and the latest manufacturing processes ensures that customers receive the highest quality products.

Our Goal and Vision

Advanced Protective Packaging is driven by the goal of providing the best possible solution for protective packaging needs. The company’s vision is to deliver these solutions with the highest level of service, constantly adapting to meet changing customer requirements.

Conclusion

Foam protective packaging is an essential component in ensuring the safe and damage-free delivery of products across various industries. With its superior impact absorption, moisture and chemical resistance, and versatility, foam protective packaging meets the demands of modern shipping and storage challenges. Companies like Advanced Protective Packaging play a vital role in delivering tailored solutions that protect products, enhance brand reputation, and ultimately contribute to business success. As industries continue to evolve, the importance of reliable and effective foam protective packaging will only grow, solidifying its place as a cornerstone of modern logistics.

Also read: Software Expert Witness